Our projects

Metal Mechanics

With the capacity to develop and produce a wide range of equipment, products, and services, Sião provides the best techniques on the market, meeting the scope of the project with a focus on customer success and execution with social and environmental responsibility, avoiding accidents and rework.

With decades of experience, Sião has expertise with various steel, Inconel, stainless steel, polymer, and other material alloys, using their properties to achieve the desired objectives.

Turnkey Supply and EPC Supply

Sião has the know-how to provide complete solutions for your project. Supply of turnkey industrial plants, including basic designs, processes, materials, construction, manufacturing and electromechanical assembly, instrumentation, control, conditioning, testing, and start-up.

Manufacturing

Our industrial division utilizes the latest technologies in manufacturing processes. Our team of engineers and specialists constantly strives to optimize processes and exceed our clients' expectations. We use a variety of materials to meet project specifications and needs. Sião provides a variety of manufacturing services, some of which are listed below:

Boilermaking

Metal Structures

Equipment

Pressure Vessels

Tanks / Silos

Assembly

The assembly is managed by professionals with extensive experience in the construction and assembly market across all disciplines: civil, mechanical, electrical, instrumentation and control, commissioning, testing, and start-up. The team of engineers and specialists plans, programs, and controls all daily, weekly, and monthly activities using state-of-the-art software. Sião has the most modern resources necessary for the assembly and disassembly of the entire industrial plant.

Engineering

One of Sião Petróleo's specialties is engineering. Our customers present their needs and Sião Petróleo provides the solution. Development and execution of product engineering, processes, basic design, detailed design, and detailed manufacturing drawings. Sião Petróleo has advanced resources and modern equipment, such as electronic systems and CAD. This structure is managed by an excellent team of highly qualified engineers and specialists with proven experience and expertise, capable of developing and executing projects in various disciplines, such as civil, mechanical, electrical, instrumentation, and control engineering.

Maintenance

Sião performs maintenance services at industrial plants in various sectors, on a plant shutdown, man-hour, and other basis. Following internal customer and QHSE standards; Focusing on employee safety, resulting in productivity and reduced process costs;

Sand control solutions

Oil and gas reservoirs exist in all types of sand, but sand-forming particles in a well stream can impair production, causing major problems with flowlines and surface production equipment.

Knowledge of the reservoir and its properties – such as particle characteristics, particle size distribution (PSD) and particle size uniformity – is fundamental to sand control design.

The choice of a sand control solution, based on reservoir PSD and other considerations, can have a large impact on the productivity and efficiency of a production well.

Today, there are several options available, disc slotted liners, wire wrap screens, expandable screens, etc.

CPT has been providing sand control solutions since 1995.

Laser Sand Control Solutions (LSCS) – Slotted 1.0

CPT was the first in the world to invent and use high-precision lasers to manufacture sand control components for use in oil and gas applications! Our sand control technology is called High Precision Laser Sand Control (LSCS).

Our high-precision lasers are each worth millions of dollars and are managed with total quality management software tools that ensure the highest performance. Why high-precision lasers?

REASON:

-

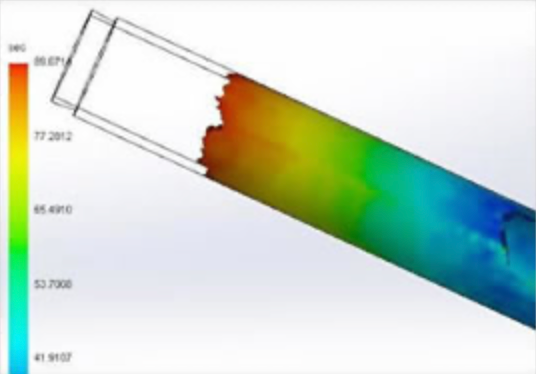

This laser maintains collapse resistance. Key for deeper wells and high pressure. The CPT laser makes slits in the casing with minimal friction and alteration of the original pipe's resistance properties. CPT has one of the highest collapse resistance sand control solutions in the world!

-

Often, screen sand control technology collapses under pressure in deeper wells, or gets stuck during implementation on jagged edges and dog legs. Many oil operators opt for slotted pipes due to the delicate nature of sand control solutions using screens.

-

The possibilities for metals are greater. Our high-precision lasers can cut any metal, whether it's W80, L80, Super Duplex, Inconel 125, Super-CR 13, or CRA 28. A wider variety of metals helps combat high H2S levels and severe well conditions that cause corrosion and erosion.

-

Often, wire screens can only be made with a limited variety of metals that cannot withstand harsh environments. It is impossible to make a wire screen for sand control from Super-CR13 or CRA 28. CPT technology allows for a wider variety of metals.

-

Above all, our high-precision lasers are more accurate and can make slits of any shape and size! Perforated linkers, slotted liners, etc., and in widths as small as 0.1 millimeters (disc slotted liners can make cuts as small as 0.3 millimeters!). This gives our customers more options for configuring their open flow area and percentage!

-

The cuts are also cleaner, more polished, and smoother, which allows for greater durability of their shape and performance.

-

It is important to note that CPT's sand control solution has the lowest clogging rate in the world for slotted liners. Our patented cut allows for a greater difference between internal and external delta P, which reduces the clogging rate of our cuts by 30% when compared to conventional keystone or straight cuts currently in use, which clog easily and lose their shape in a short period of time! This means fewer changes, lower operating costs, and less production downtime! Saving our customers considerable time and money.

In short, a completely different type of grooved liner replaces Wire Wrap Screens (WWS), which are more expensive, weaker against corrosion and have a lower resistance to collapse when compared to our high-precision laser sand control solutions.

Sand/Oil/Water/Gas Control Solutions – Slotted 2.0

Oil and gas reservoirs exist in all types of sand, but sand formation particles in a well stream can impair production, causing major problems with flow lines and surface production equipment.

Knowledge of the reservoir and its properties—such as particle characteristics, particle size distribution (PSD), and grain size uniformity—is critical to sand control design.

The choice of a sand control solution, based on reservoir PSD and other considerations, can have a major impact on the productivity and efficiency of a production well.

Today, there are several options available, including disc slotted liners, wire wrap screens, expandable screens, etc.

CPT has been providing sand control solutions since 1995

Our Sand/Oil/Water/Gas control system, named Slotted 2.0, allows our customer to:

-

CONTROL OVER WHAT IS BEING PRODUCED – Determine whether you are producing water or gas (this gives our client complete control and flexibility).

-

CONTROL OVER WHERE YOU PRODUCE – Where exactly that water or gas level reached and when (which allows complete control of completions/production).

-

Slotted 2.0 is an efficient extraction and monitoring system.

-

Allows inflow monitoring directly from the surface, without extra personnel on site.

-

COST EFFICIENT

-

NO MOVING PARTS OR NEED FOR ELECTRICITY